Magnetic inductive loop : LP-S

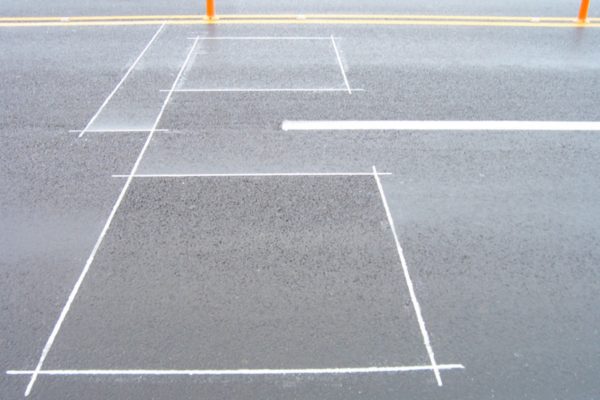

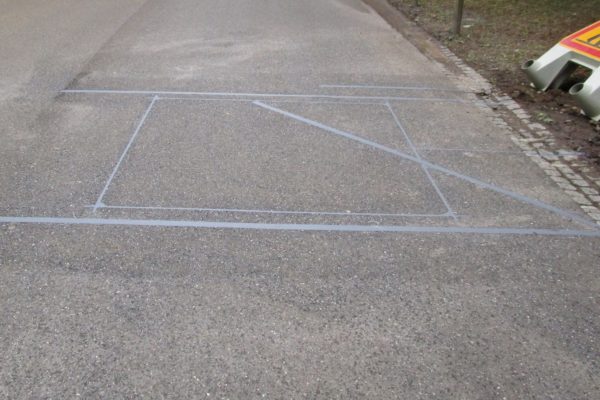

The inductive loop or “loop” is a special ECM cable installed in the road (concrete or asphalt), to detect the metallic mass of vehicles.

Thus, detection of vehicles with a “loop” is used in many applications such as :

- Road and motorway counting and classification,

- High speed Weigh in Motion (> 20km/h),

- Toll classification,

- Preselection of infringing vehicles.

Key features :

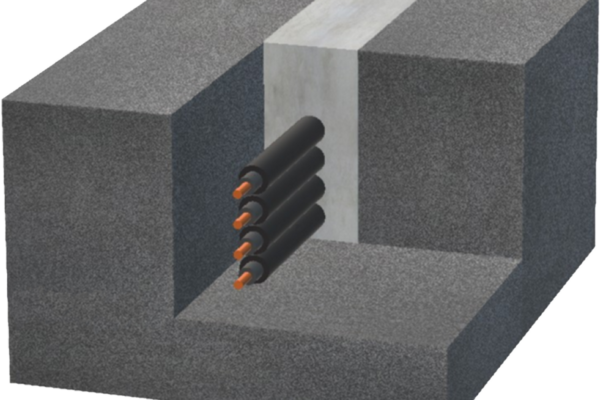

The ECM “loop” consists of 4 different parts, a :

- Special 1.5 or 2.5 mm² cable with double insulation,

- Waterproof connection,

- 25 or 50 metre twisted return cable,

- Resin to fill the cable track.

MTBF (Mean Time Between Failure) : 8 years